One of the rarest events occurred in the history of global economy where at the onset of the pandemic, the world shut down and requested people to stay home. Essential services had to be defined by governments, with special permissions tendered to allow movement of people. At such a time, it became difficult for businesses, especially small-to-medium businesses (SMBs) would be affected with figuring how to manage supply chains during the pandemic became a serious issue.

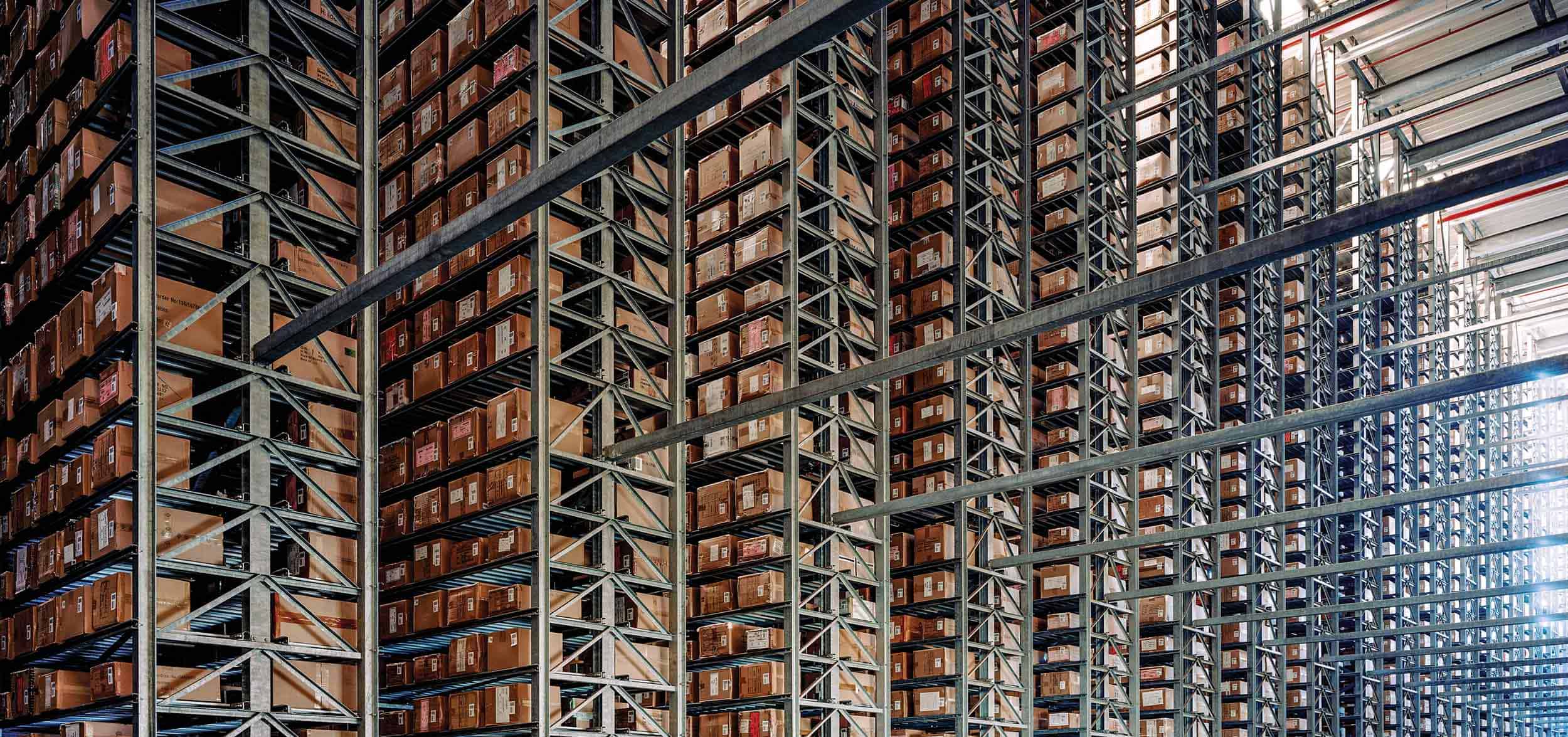

It’s no surprise that supply chains were affected. Not only are they a globally network process, but it is also one that required manpower which was greatly affected with the stay-at-home order from various governments at different times. Companies that dealt with smaller inventory/stocks were luckier, as they were able to scale back their processes yet larger companies with more inventory had trouble with scalability in response to the pandemic.

China being one of the largest manufacturing/production regions in the world, mostly due to their economies of scale, be it for parts or for whole goods, were heavily impacted making it difficult to manage supply chains the world over who were dependent on their outputs. With factory closures and once they opened, slower productions meant that they were unable to keep up with the demands. Whilst some were able to manage their supply chains with merely scaling back the delivery times or on a preorder basis, others were unable to stay afloat.

However, we can learn from these situations in how to manage supply chains for future mitigation. The following are great insights based on a three-step approach

Preparation

- Plan for the worst – Setting up a plan that accounts for various scenarios and instances will help mitigate the losses you may incur my factoring alternate courses of events.

- Setting up an emergency operations center and protocols – In the event your staff is unable to make it to their respective places of work for whatever reason, setting up an alternate emergency operations center to direct all work and instructions can be useful especially during a critical or disaster level event

- Understanding supplier’s processes well – ensuring you understand the workings of your supplier and maintain good open communication will allow you to prepare for events and react accordingly.

Response

- Response times to accurate information – receiving accurate and timely information can allow you to spring into action with minimum delay which means that you are not wasting precious time especially at a time where time is money.

- Precautions to meet consumer demands – by setting up a demand-forecasting system that accounts for various changes in consumerism will assist in decision making and ensure that strategic choices and decisions are being made.

Recovery

- Planning Ahead – planning ahead is crucial to ensure you see the end of the emergency or crisis. With due diligence and planning, you will be able to bounce back with proper strategies.

- Learning from past events – With any crisis event, we look back and learn from them for future growth and sustainability. Make sure to update your playbook accordingly to minimize losses in future and create efficiencies in them especially in how to manage supply chains better in future.